Round bottle labeling machine common failures and maintenance methods

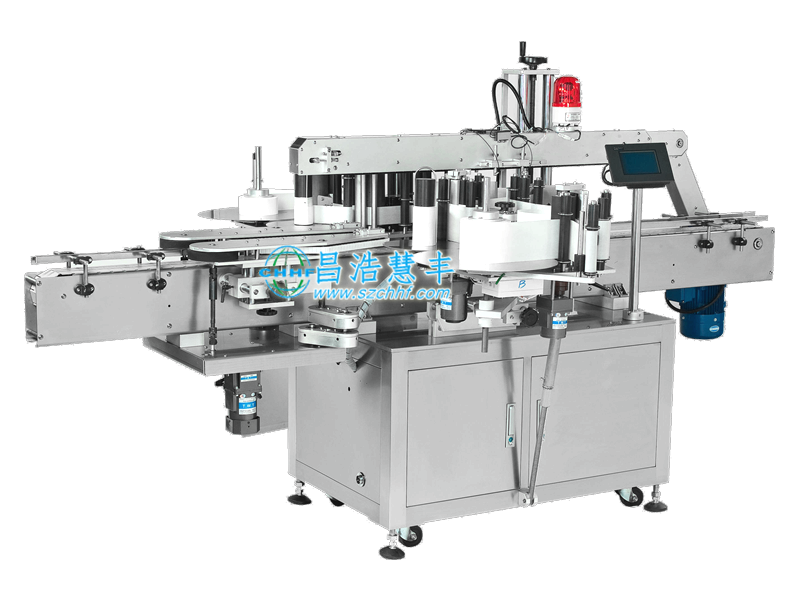

Round bottle labeling machine, dedicated to a variety of round bottle labeling, labeling function can be attached to a single label and double label, front and back double label spacing can be flexibly adjusted, optional circumferential positioning detection device, can be achieved in the circumferential surface of the specified location labeling. Round bottle labeling machine will inevitably have some small problems after a long time, the following, Zong Yu automation to tell you the common failures of round bottle labeling machine and maintenance methods.

A, continuous labeling problem: this situation may be related to the sensitivity of the electric eye detection, adjust the electric eye to make it work properly. The problem still can not be solved may be the label beyond the scope of application of the selected electric eye, or electric eye damage, you need to consult the round bottle labeling machine manufacturers. Another reason for the label away from the bias, the electric eye did not detect the label, before and after adjusting the electric eye to detect the position can be.

Second, the label is attached to the active axis: may be due to the glue is too thin, in the label after the active axis, the glue outflow to the active axis. Or too much glue, adjust the interval between the scraping block and the glue coating wheel.

Third, the round bottle labeling machine paper feeding is not smooth: the reason may be, the paper limit adjustment is too tight, re-adjust the limit block; paper jaws with adhesion, cleaning the paper jaws; splitting paper too many sheets, adjust the gap between the splitting wheel and the splitting platform.

Shenzhen Changhao Huifeng Industrial Co.

9F, Zhengke Times, No.17, Industrial Road 1, Da Wang Shan, Shajing Street, Baoan District, Shenzhen

Copyright@2023粵ICP備15020808號